|

|

|

|

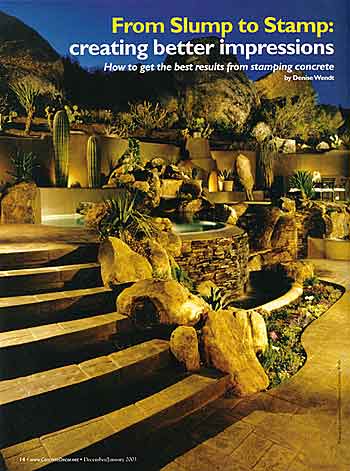

From Slump to Stamp: creating better impressions

How to get the best results from stamping concrete.

BY DENISE WENDT

Stamped concrete offers an inexpensive alternative to state, brick and stone materials while creating the same visual effect. But there are a few tips every installer should remember. Concrete Decor asked veteran concrete professionals to share their techniques for success.

Mud that's just right

"Concrete is the hardest work on this planet, bar none, if it gets away from you," says Richard Smith, who owns Richard Smith Custom Concrete in West Hills, Calif. "But with proper planning and a lot of common sense, that doesn't have to happen."

"When you finish or stamp concrete it is kind of like Goldilocks' porridge," says Tom Ralston, owner of Tom Ralston Concrete in Santa Cruz, Calif. "You can't have it be too soft or too hard. It has to be at just the right consistency." Too wet and the concrete pulls the stamps, leaving suction marks. Too dry and it will not leave any substantial embossment or impression.

Concrete tool distributor and trainer Bart Sacco owns and operates Concrete Texturing Tool & Supply in Throop, Penn. "You want concrete that's workable but not excessively wet," says Sacco. He uses a 4- to 4.5-inch slump. "As the season progresses I'll pour tighter to compensate for evaporation," he says.

Michael Riggs owns Progressive Concrete Works Inc., in Phoenix. "We place all concrete at a maximum slump of 5 inches," says Riggs. "Consistency is very important and every load should be placed at the same slump so that the texture and color will be consistent." A lower slump can also prevent oozing between stamps, says Riggs.

Michael Riggs owns Progressive Concrete Works Inc., in Phoenix. "We place all concrete at a maximum slump of 5 inches," says Riggs. "Consistency is very important and every load should be placed at the same slump so that the texture and color will be consistent." A lower slump can also prevent oozing between stamps, says Riggs.

To ensure a consistent impression, Riggs places 4 inches of aggregate base course and then compacts the subgrade before placing any concrete. "We have found that this helps us achieve a more consistent finish and also helps to prevent efflorescence," he says.

As with all concrete, weather and sunlight affect surface hardness. Surface hardness has a significant impact on the texture as well as the color. When setting up a job with areas in direct sunlight and areas in shade, Riggs says to consider how the inconstancy will affect the finishing. If possible, consider placing the areas separately.

Smoothing suction marks

Ralston recommends using a texture roller or a lambswool paint roller to smooth out suction marks that can result from stamping wet concrete. Wedged jointing rollers can be used to knock down suction marks, smooth ridges and clean up the joints between the stamp patterns.

"Many times the oozing is a characteristic a bad set of tools," says Riggs. If you have a set of tools that you have had oozing problems with in the past, replace the tools, he says.

Timing is everything

"Timing is essential in patterned concrete work," says Sacco. He urges contractors to know the properties of the concrete they're working with, to know the weather conditions they'll be working in and to adjust their timing, appropriately. "Depending on the time of the year, you'll either have to speed up or slow down to achieve a nicer stamped impression," says Sacco.

"When planning and scheduling a project, don't place more concrete than you can handle," says Riggs. "Remember the owner is paying you a premium for the stamped concrete and is going to be critical of every small detail."

Charles Leland, owner of SureCrete Design Products in Dade City, FL, agrees. "Don't get greedy," says Leland. "Start with smaller, controllable amounts to stamp in a work day. And don't be afraid to hire a consultant for a job to ensure success."

Know your stamps before you get to the job site, says Ralston. He recommends putting down about an inch of sand in a 15x15-square foot area. Wet that down and lay out your stamps. "Do a dry run so you know how these stamps are going to interlock," he says.

Above: Ashlar slate with a visible repeat.

Below: Running the pattern at a 45-degree angle eliminates unwanted lines.

Be aware that the tools will also draw moisture if left on the slab too long, affecting the texture as well as the color, says Riggs.

Tool selection, use can help reduce repeats

Some stamps, such as a European fan pattern, are designed to be used throughout an entire pour, repeating over and over again. But a visible repeat, in an ashlar slate for example, is undesirable. For such a project, use a 3-pattern stamp, with patterns labeled A, B and C or blue, gold and red. "The different colors dictate a different rock pattern to help you reduce the look of using a mold." says Sacco. Interchange these three different patterns frequently throughout the slab.

Smith avoids unwanted lines by turning some patterns 45 degrees. "A pattern, such as ashlar slate, that isn't intended to be a straight-line pattern becomes a straight-line pattern when you start stacking it," says Smith. "The way to get around that is to turn it on a 45 degree angle and all of a sudden all those lines disappear."

Bands and borders can also break up noticeable lines that develop on large areas. "Hide" control joints by incorporating them into the design with complementary bands and orders, suggests Leland. "Banding with a contrasting color or texture will help break up a large field," says Riggs.

Borders can also help downplay slight color variations that can result from different pours.

Sacco uses Creative Images tools to cover larger pieces of ground with fewer placements of the mat. The larger Creative Images stamps can break up noticeable lines that develop on large areas. Note that two men must lift thew larger stamps simultaneously to avoid scrubbing the surface of the concrete.

Admixtures can also help

Admixtures do many different things and some can help minimize the problems that can occur when stamping concrete.

Calcium chloride and Polar Set accelerate set time and allow the bottom of the pour to dry at the same rate as the top, promoting a good stamp. Polar Set doesn't have any adverse effects with rebar while some colors are adversely affected by the calcium chloride. So consider your job when choosing an admixture.

"Fritz-Pak makes good admixtures that you can add on the job site," says Ralston. This is especially useful when the site is hotter or windier than where you started that morning. "Fritz-Pak step retardant can give you the extra time you need in those conditions," he says.

Riggs uses admixtures to control set times and water cement ratios. But watch out for crusting and surface cracking with some high-range water reducers.

Riggs likes to use dry shake color hardeners, which offer a broad range of coloring options. "Installers need to apply the hardeners evenly to avoid clumps and wet and dry spots," says Riggs.

"Some detailed stamps require a creamier cement," says Smith, who adjusts for this by adding a little color over the top of the cement. "The extra color gives the concrete a slightly fattier surface or a creamy base," says Smith.

Tamping tips

Tamping well requires practice and experience. Our pros had these tips on which tools to use and how to use them.

"We like to use the tamper because it allows us to use different amounts of force to address the arm of the slab that have not set up consistently," says Riggs.

Leland uses a tamper to remove footprints.

Smith usually uses a square tamper, but some jobs require a different approach. "If we're doing a driveway or pool deck that has a drain basin, even the standard l0xI0-inch square tamper will leave an outside impression." Then he turns to a thin, 8-inch round piece of plywood to tamp down the stamp. "When you get into different elevations or when the slab tends to roll up and down, you want to try a different method."

Sacco uses 2x10 or 2x12-inch pieces of lumber to seat his mats. "When the concrete is very fresh, we'll lay the mats out, keeping them as tight as possible. Then instead of stepping on the mats, we'll lay a strip of lumber down and walk on that, distributing our weight more evenly-" He uses two pieces of lumber, putting one in front of the other, and leapfrogs from one to the next.

Training

All our professionals agree that is crucial, whether you're a veteran of the trade or just starting out.

"If you are not constantly learning in this business you are in big trouble," says Riggs. "Since 1970 we have placed literally millions of square feet of stamped concrete and every day is a learning experience."

"Training is extremely important," agrees Ralston, who also teaches stamping and acid-staining techniques around the country. "'Any seminar you can send a person to is beneficial. You will always learn something and they can make good networking connections when attending seminars."

Twenty-five-year concrete veteran Smith says you're never too experienced to learn something new, "Wherever I can get my hands on a good training course, I still go. There are constantly new techniques, new chemicals coming out and new ways to apply color."