|

|

|

|

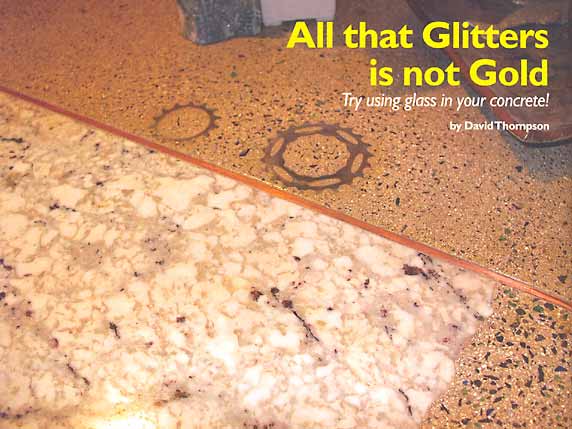

All that Glitters is not Gold

Try using glass in your concrete!

by David Thompson

If you want concrete that truly sparkles and shines, put some glass in the mix.

Glass aggregate can replace part or all of the sand and gravel in concrete, for effects that range from colorful terrazzo, to granite- or marble-like finishes, to concrete that reflects light like a mirror. Glass aggregate can even be used to produce concrete that literally glows.

"One of the prettiest countertops ever saw had clear glass aggregate in white concrete," says Wes Vollmer, of Alternative Finishes in Texas. "There were lights underneath it that shone through and made the whole thing glow faintly. It was just unbelievable.

Glass aggregate can also win a project the "green" stamp of approval, since it almost always comes from recycled glass, saving landfill space and requiring no mining.

Glass aggregate is typically graded by color and size. Sizes can range from sixinch rocks to gravel-sized pieces to a fine talc-like powder. Polishing, grinding or other exposed aggregate techniques are employed to reveal the glass. Or glass can be seeded on the surface and then exposed.

Colored glass can be coordinated with the matrix of integrally colored concrete. In general, lighter colors of glass are used in darker matrixes, and vice versa. But not always.

A dark brown glass in a dark brown matrix can have an appeal all its own. Mixing light and dark colors of glass will give you a terrazzo effect. If you use clear glass aggregate, it will take on the color of the matrix, and it will add the most depth. Since glass is acid resistant, acid staining will color the surrounding matrix without affecting the color of the aggregate.

Finely ground glass can add background colors to the matrix. Using finely ground clear glass in place of sand can make for purer colors of concrete. Finely ground glass also lends itself to highly polished finishes. A marble or granite took can be attained by putting a high polish on concrete made with finely ground, earth-toned glass aggregates.

As for strength, glass aggregate can match, exceed or fall short of traditional aggregates, depending on size. Studies have found that very finely ground glass aggregate used in place of sand actually increases the strength of the concrete, whereas gravel-sized glass aggregate decreases strength. Mixing fine and coarse glass aggregates can have a net effect of zero, rendering concrete no stronger or weaker than that mixed with traditional sand and gravel.

Buy it or bash it

Glass aggregate can be obtained from a variety of sources. Locally, recycling centers may have cutlet - crushed bottles and other glass - cleaned and sorted by size and color. Nationally, specialty glass manufacturers melt down bottles and window glass to produce glass aggregate for terrazzo floor contractors, landscapers and decorative concrete artisans.

And then there's always your personal stash of empty beer bottles. With a small investment in a high-impact glasscrushing machine, you can make your own cutlet, though some contractors opt to do it the hard way - with the help of a scrub brush to remove labels, safety goggles to protect eyes, and a hammer to do the dirty work, The use of a good crushing machine is preferred, though, because it doesn't produce the sharp, dangerous edges of the hammer-the-bottle method.

Tom Ralston, of Tom Ralston Concrete in California, has glass aggregate connections that include a hard-core beachcomber who collects heaps of beach glass, and a glassblowing shop, which always has an interesting mix of aggregate just waiting to be raked off the floor. He has also mined his own stash of empties, the down-and-dirty way. "I had my crew sitting around like Cro-Magnon creatures, breaking beer bottles with hammers into a cardboard box," says Ralston. "It was like an ancient ritual."

Specialty glass aggregates made from recycled glass that is melted down and re-formed give you a different look than plain old crushed glass. Crushed bottles and window glass tend to be flat, with parallel sides, whereas specialty glass aggregates can have fuller, more irregular shapes, like crushed gravel..

"Crushed bottles don't have as much depth and sparkle," says Ken Thornley, general manager of Utah-based Heritage Glass, one of the country's largest specialty glass manufacturers. "But with the more irregular shapes, light bounces off it like it does off the facets of a diamond."

Sparkle notwithstanding, some decorative concrete artisans prefer cutlet for the simple reason that it takes less polishing or grinding to bring out flat pieces of aggregate than it does to reveal more multidimensional aggregate.

When maximum sparkle is desired, Heritage Glass has a silver-coated glass aggregate that reflects light like a jewel, Thornley says. But if it's not so much sparkle as shine that you want, both Heritage and American Specialty Glass, another Utah-based specialty glass maker, have crushed mirror aggregate. Mirror chips can add a hard reflective shine, and finely ground mirror aggregate can add a subtle iridescent sheen.

"If you use 30-mesh mirror or smaller, and put it in the background matrix, it gives you a sheen like granite," says Jim Silver, general partner with American Specialty Glass.

Pricewise, specialty glass can go for as little as 30 cents per pound for large quantities of some types, and up to $6.35 per pound for Heritage's silver coated aggregates. Cullet goes for whatever the local market rate is.

Alkali-silica reaction must be considered

When using glass aggregate outdoors, or anywhere else that the concrete will be exposed to moisture, beware of the dreaded alkali-silica reaction, an unhappy phenomenon in which the silica in glass and the alkali in cement create a gel that swells in the presence of moisture. The reaction may happen right away or it may take 20 years, but in either case it can cause cracking. Any source of moisture can set it off, including mopping, using excess water in the concrete mix, and so forth.

But the alkali-silica reaction can be prevented. Engineers at Columbia University, committed to developing more environmentally friendly building materials, discovered that the reaction can be avoided if the glass is ground finely enough to pass through 50-mesh or smaller screen. They also found that the mineral admixture metakaolin will suppress the reaction - an effective but expensive solution.

"We replace 20 percent of the cement with metakaolin, which may double the cost of the concrete, because metakaolin can cost as much as four or five times what cement costs," says Christian Meyer, a professor of civil engineering at Columbia.

Other studies have shown that fly ash suppresses alkali-silica reaction, Meyer says. "It's not as effective as metakaolin, but it's cheaper," he says.

The Columbia researchers also found that green glass does not cause the alkalisilica reaction, due to the chromium oxide used to get the green color.

Of course, keeping out moisture with a good sealer (presuming you haven't used too much water in the mix) will also suppress the reaction.

In the decorative concrete arena, most glass aggregate currently goes into countertops. But there's really no reason it can't go into floors, walls, furniture or anywhere else decorative concrete is found - indoors or out.